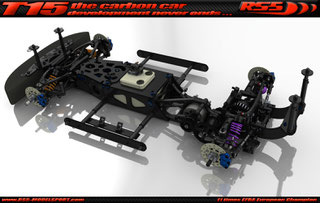

RS5 - T15 Touring Car Features

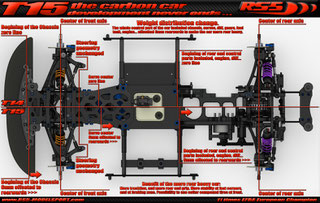

Weight Distribution Change

The weight distribution of a car has huge effect to the handling. More weight to an axis

(front or rear) increases the grip of that particular axis by giving more load to the tires. In our case we want to increase the rear end grip of the car a bit, so we dedicated to make the car

lighter at front and heavier at rear. To do this we created new wishbones that are offseted to front and some more parts. With this modification the complete center part of the car was offseted

to rearwards.

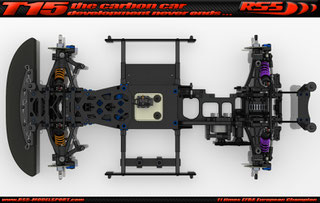

Additional weight

We find a perfect place on the rear end of the car, under the differential, where we can add some extra weight's, when more rear end grip needed. To fixing it we made 4pz of M3 screw thread to the alloy chassis. The chassis is exactly the same as our previous models (T12, T13, T14) only has this 4pz extra screw thread. The additional weights will be available as an option part.

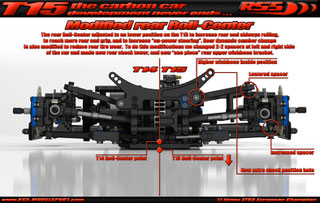

Roll-Center adjustment

Between the weight distribution changes, the roll-center play also a

very important part to the handling of a car. We increased the front roll-center of the car, by changing some spacers, and we lowered the rear roll center by changing some spacers and making new

rear shock tower, and upper wishbone bracket. The upper wishbone braket made from one-piece to make more stiffnes and precision.

With the increased front roll-center the front end of the car will roll less sideways, and that reason generate less pressure/grip to the front tires, and have less tendency of traction-rolling and give a bit more rear end traction. With the lowered rear roll-center the car will roll sideways more, and with them generate more pressure/grip to the rear tires, and generate more steering during acceleration (on-power steering).

New wishbone and roll-bar holder

The make of the new wishbones was necessary reason of the weight distribution change. It’s key features are the same as the previous modes, like zero play Steel/Brass hybrid ball joints, and the use of high quality airplane aluminum. But during the design change we made the front wishbone's stiffener rib a bit thicker to support more the front anti-roll bar. To reduce vibration of the rear roll-bar we lightened it as much as possible. The rear roll-bar holder has an plastic ball insert, to reduce vibration, and to avoid braking.

New wheel hubs

We lightened our wheel hubs by 40 grams, to reduce the unsprung mass. This weight reduction also support the add of additional weight to the rear of the car. The new wheel hubs also has smaller bearings to reduce friction. The hubs are now the direct holder of the brake calipers (no more need the 75460 part), to reduce brake caliper flexing, and make an even more precise fit.

New servo saver

Our new servo saver has centering balls, to make a very precise and strong, click feel centering effect. With this method the steering system has almost zero dead zone/play. The strongnes of the servo saver is adjustable, and has double ball bearings design to work play free and gently.

New diff. carrier and stiffener bracket

Reason of the weight distribution change we need to make new diff. carriers to offset the rear shock tower 6mm forward, and to fix the new shorter rear wishbones, and to keep the same rear track-rod angel as at the previous models. The new diff carriers are also lighter and has less screws for easier diff. change. We made a new diff. carrier stiffener bracket with “X” design to support extreme high, rear droop setup by giving more place for the rear roll-bar.